Products

Optomechanics

Mounting, fine positioning, and alignment hardware for CGHs and test optics

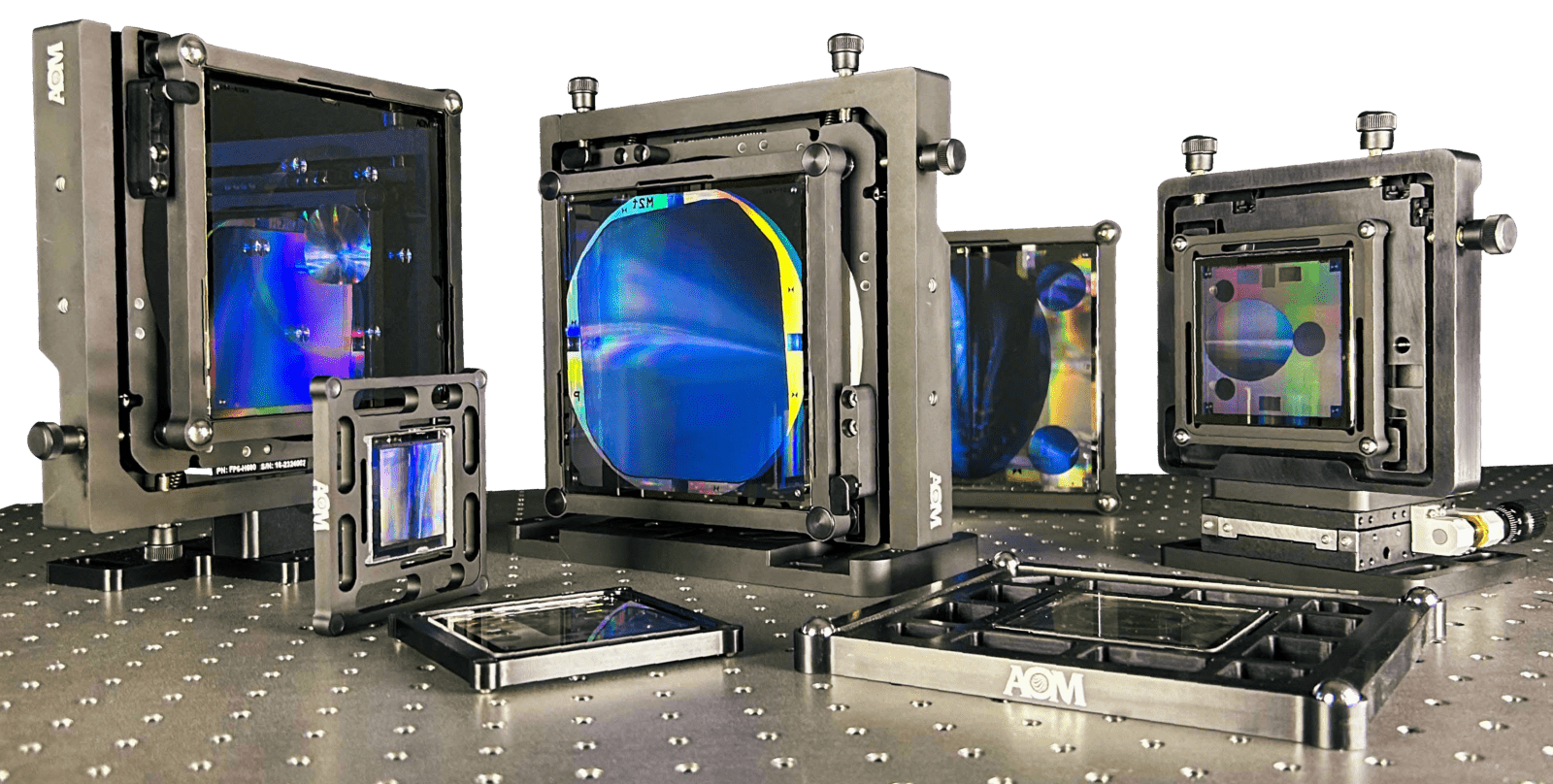

Mechanics for Optical Testing

AOM stages, CGH mounting hardware, and alignment accessories enable streamlined testing of optical elements and systems and ease of alignment with smooth, stable, and repeatable positioning.

CGH cells and alignment stages are designed for use in any orientation and mounting combination: horizontal interferometer optical axis for table use, vertical upward-looking or downward-looking interferometer optical axis for gravity-assisted tests.

CGH Cells

AOM CGHs are provided in a mechanical cell, enabling easy and repeatable kinematic mounting to alignment stages, ease of handling, and provide reliable low-distortion housing for the CGH glass substrate.CGH cells are available in 3 different size formats and house various CGH substrate formats and stage compatibility. When specifying a CGH, it is important to ensure the cell is compatible with the stage hardware you have available.

| C3: 3-Inch CGH Cell | C6: 6-Inch CGH Cell | C9: 9-Inch CGH Cell | |

|---|---|---|---|

| CGH Substrate Compatibility | 3-inch (S3) 2-inch (S2) | 6-inch (S6) 3-inch (S3) | 9-inch (S9) |

| Alignment Stage Compatibility | FP3 FP6 (requires C6AC3 adapter) | FP6 Diffraction International M6025 positioner | FP9 |

| Mounting Balls | 1/4-inch diameter, stainless steel, mounted on both sides of cell | 12 mm diameter, stainless steel, mounted on both sides of cell | 1/2-inch diameter, stainless steel, mounted on all edges of cell |

CGH Cells

| C3: 3-Inch CGH Cell | CGH Substrate: 3" (S3) Compatibility: 2" (S2) Alignment Stage: FP3 Compatibility: FP6 (requires C6AC3 adapter) Mounting Balls: 1/4" diameter, stainless steel, mounted on both sides of cell |

| C6: 6-Inch CGH Cell | CGH Substrate: 6" (S6) Compatibility: 3" (S3) Alignment Stage: FP6 Compatibility: Diffraction International M6025 positioner Mounting Balls: 12 mm diameter, stainless steel, mounted on both sides of cell |

| C9: 9-Inch CGH Cell | CGH Substrate: 9" (S9) Compatibility: Alignment Stage: FP9 Compatibility: Mounting Balls: 1/2" diameter, stainless steel, mounted on both sides of cell |

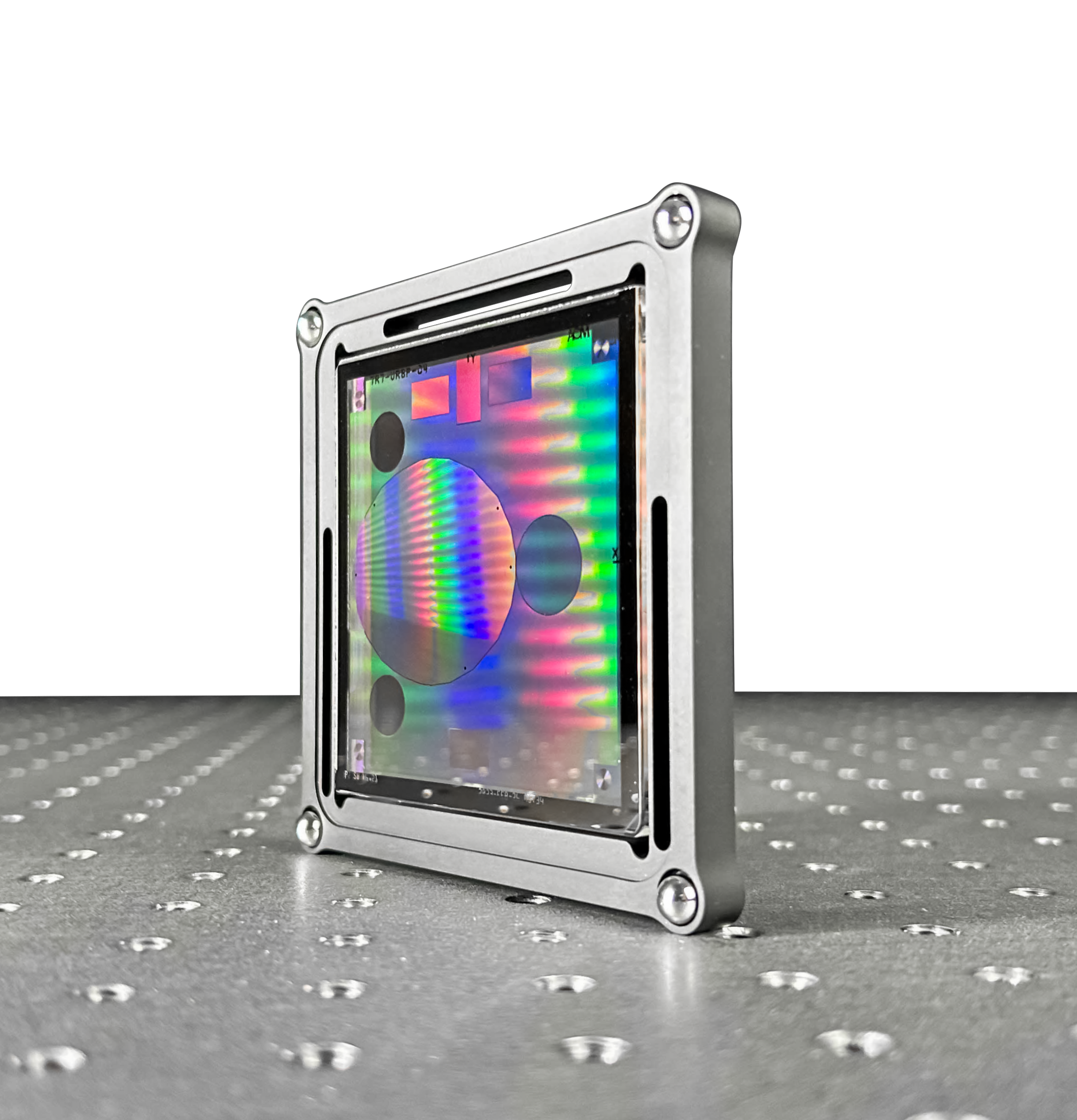

C3 CGH Cell

Small format for affordable small format CGHs. The C3 cell mounts directly to the AOM FP3 alignment stages.

1/4" mounting balls on 3.5" square pattern,

both sides of the cell

3-point flexure-mounted substrate and

AR coated back surface

2-inch cylinder CGH substrate in 3-inch cell

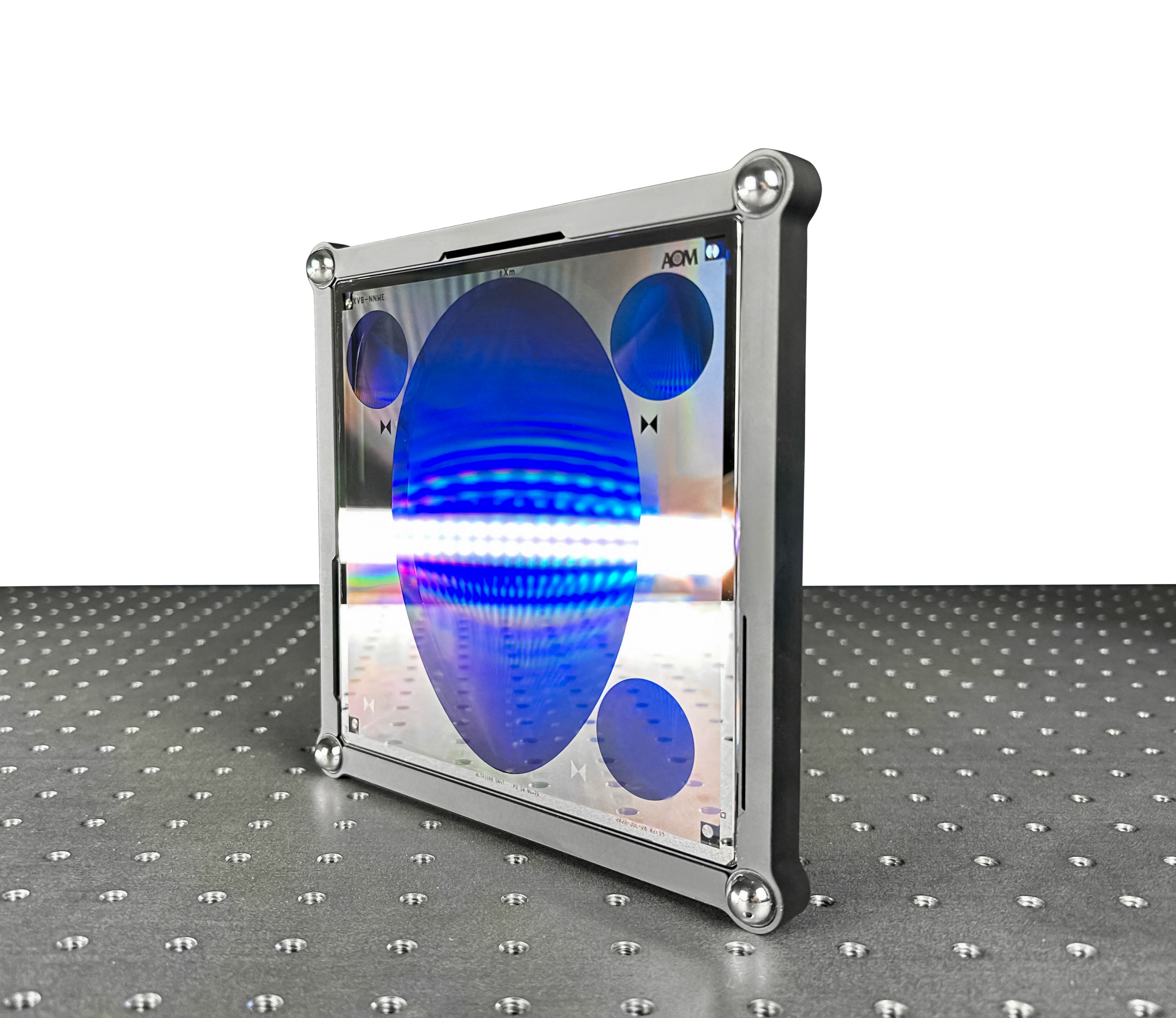

12mm mounting balls on 6.375" square pattern,

both sides of the cell

3-point flexure-mounted substrate and

AR coated back surface

3-inch CGH substrate in 6-inch cell

C6 CGH Cell

Medium size format for standard 6-inch CGH mounting. The C6 cell mounts directly to the AOM FP6 alignment stages.

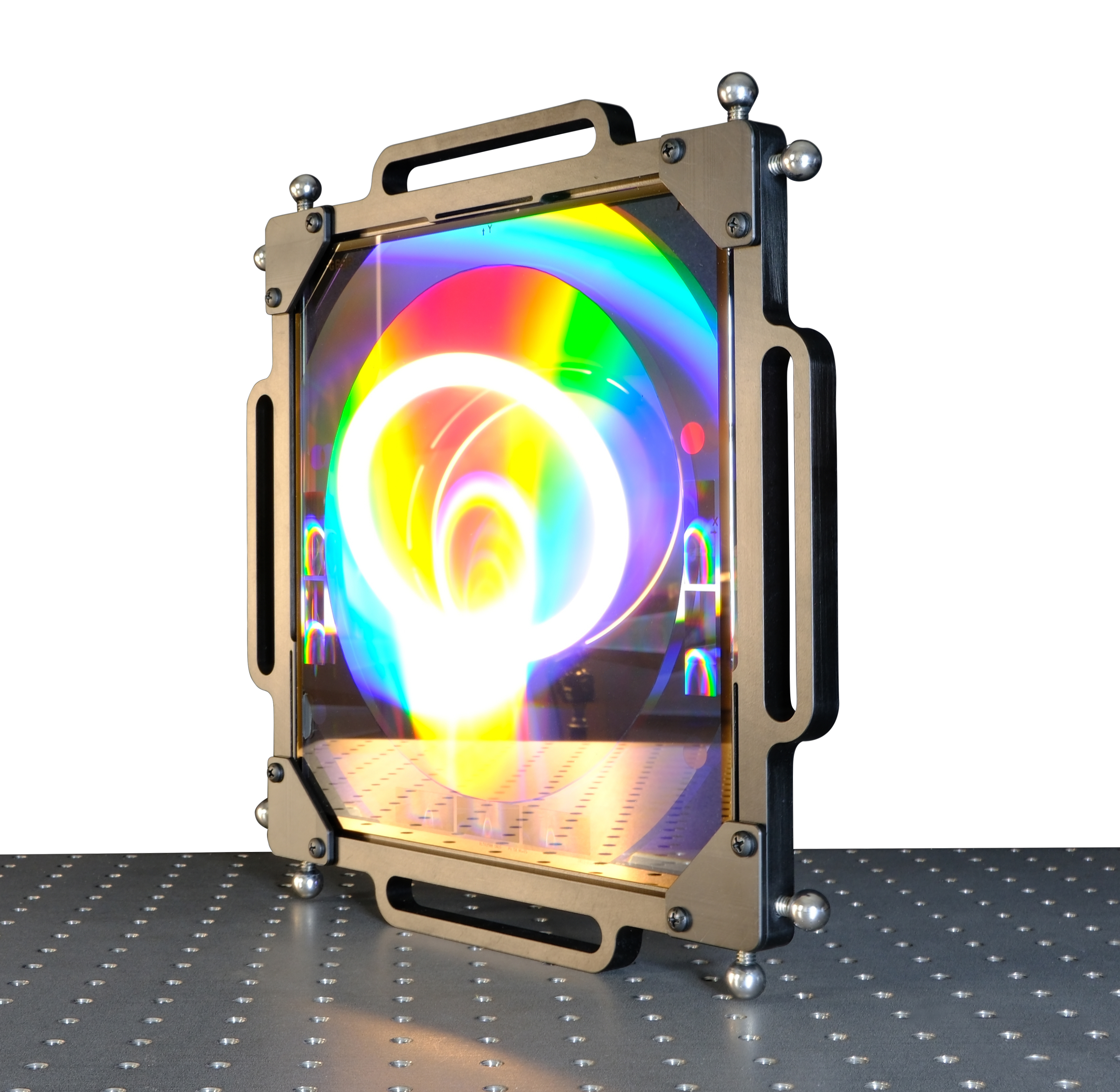

C9 CGH Cell

Large size format for standard 9-inch CGH mounting. The C9 cell mounts directly to the AOM FP9 alignment stage

1/2-inch mounting balls on all four edges for secure mounting to FP9 stage

Anti-reflection coated back surface

3-point flexure-mounted substrate

Alignment Stages

AOM FP alignment stages accept CGH cells and provide repeatable and stable positioning with removal and reinstallation through a magnetic kinematic interface design.

Three alignment stage size formats each accept a specific CGH cell format – 3, 6, and 9 inches. All stages include smooth and stable 6-degree of freedom fine positioning, kinematic magnetic receivers for CGH cell mounting balls, multiple centerline height configurations that match interferometer standards, and enable any mounting orientation.

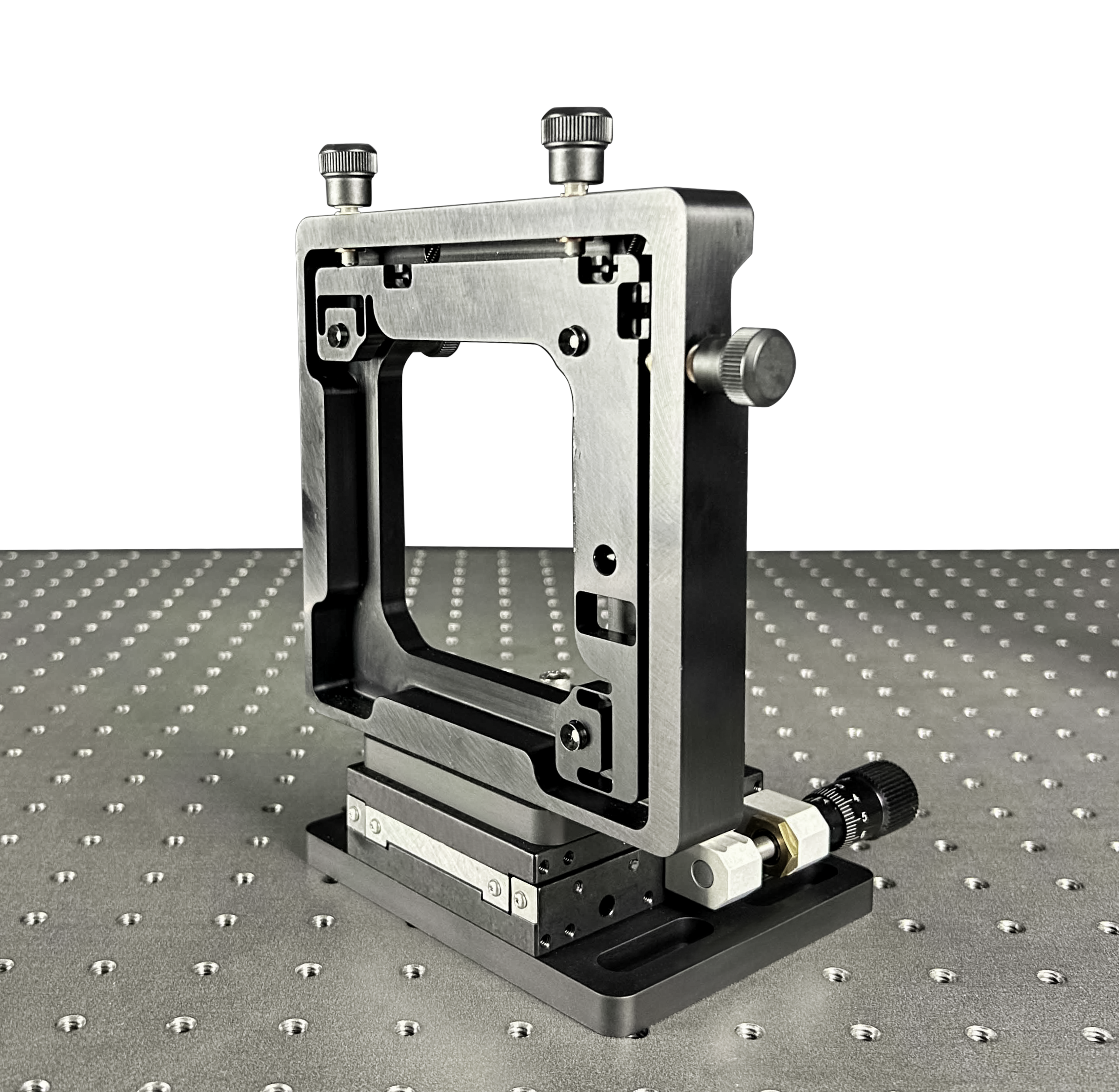

FP3 Alignment Stage

Compact, affordable and flexible. The FP3 stage enables mounting and fine alignment of the 3-inch CGH cell format (C3).

Linear z-axis for easy fine focus adjustment

Magnetic kinematic CGH cell receptacles

for 1/4" mounting ball

Mount in any orientation:

horizontal, vertical up or down-looking

FP3 stage with S3-C3

CGH assembly mounted

Kinematic interface and safety clips for positive lock of CGH assembly

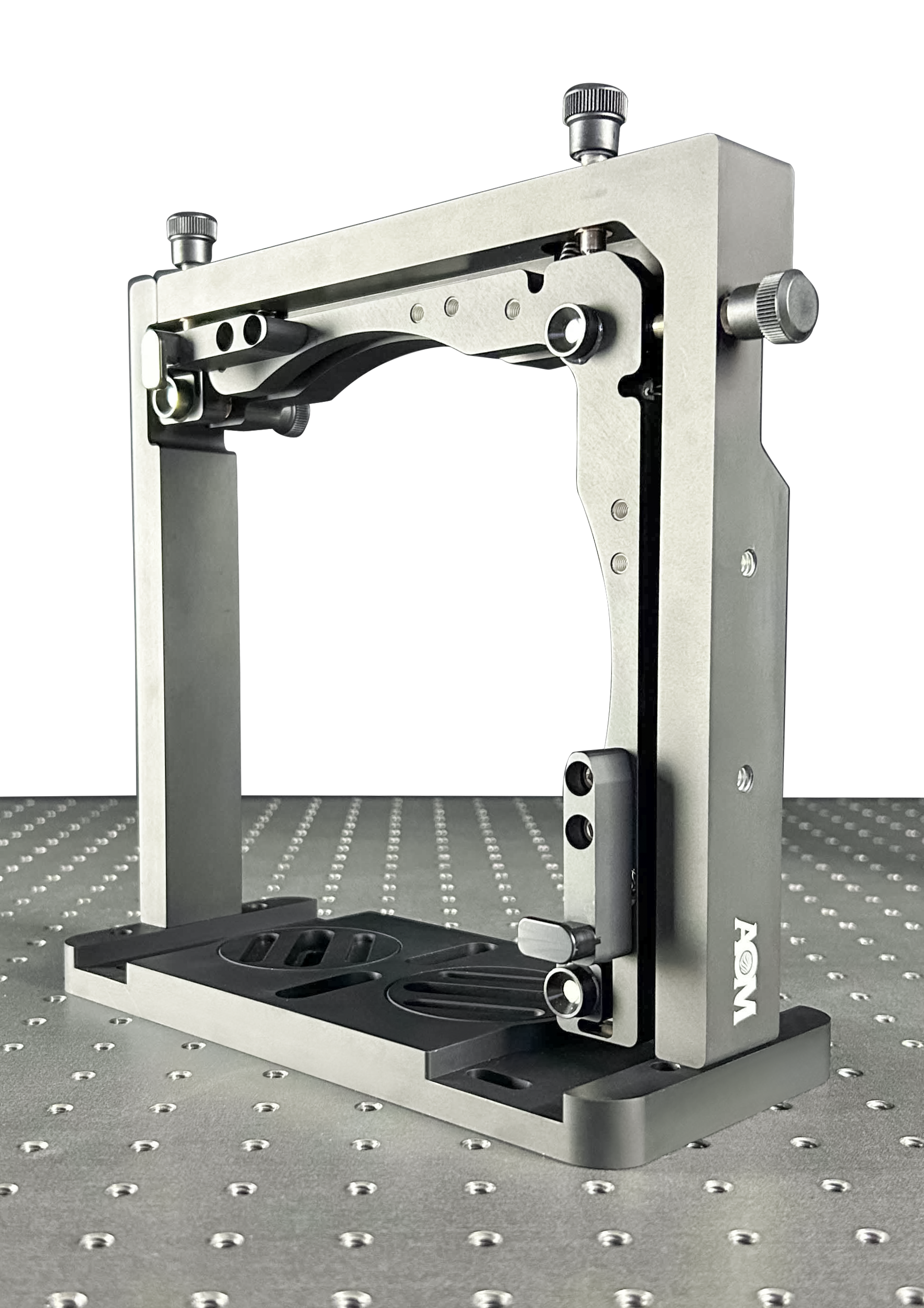

Infinitely adjustable mounting pucks, mount the FP6 in any orientation

Configurable stage - mount the alignment frame front, center, or rear for optimal clearance and working distances

6" centerline height configuration

FP6 Alignment Stage

Stable and reliable workhorse. The FP6 stage enables mounting and fine alignment of the 6-inch CGH cell format (C6) and its associated CGH substrate size formats.

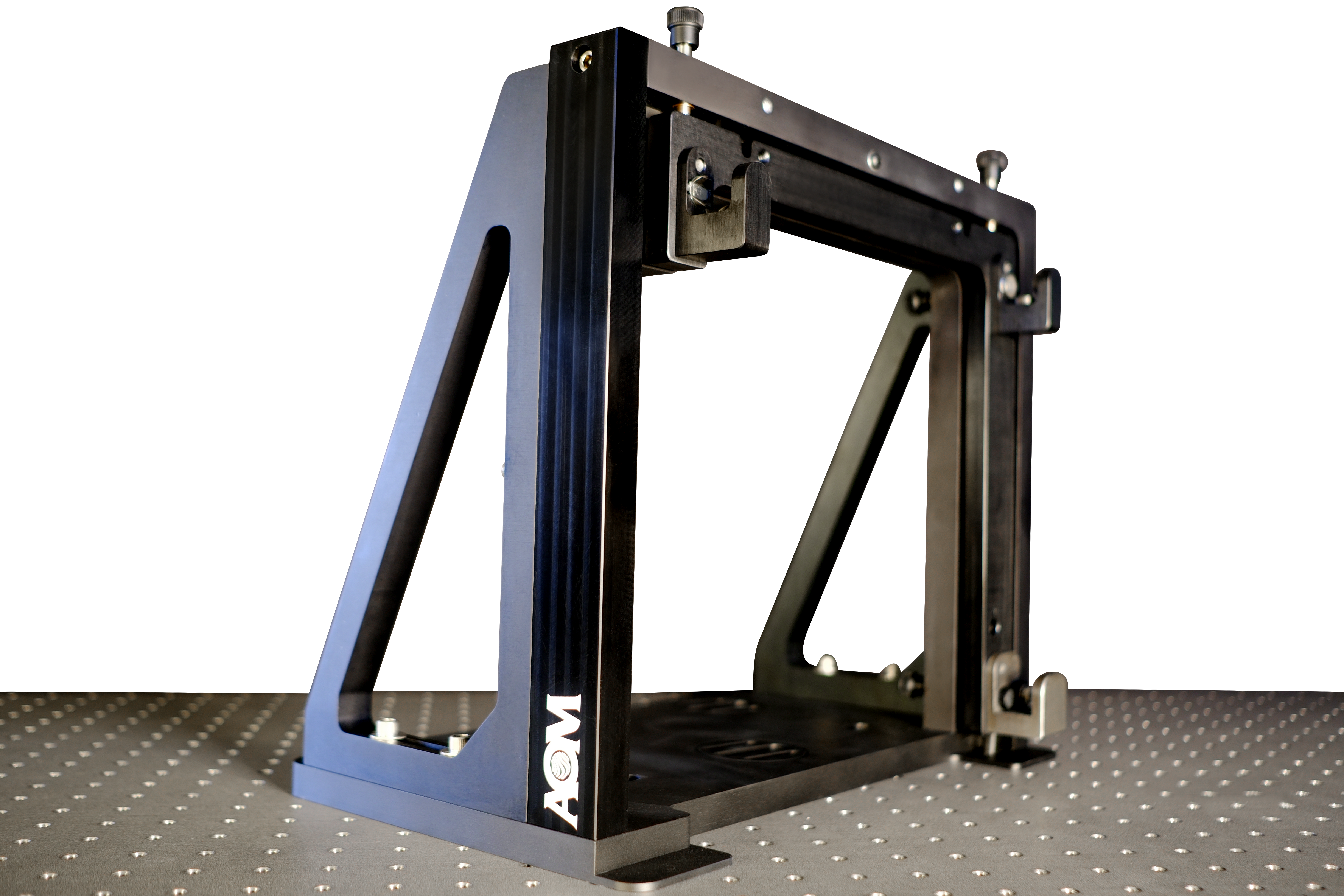

FP9 Alignment Stage

Built for stability with large format CGHs. The FP9 stage is purpose-built for mounting and fine alignment of the 9-inch CGH.

Kinematic and secure mounting in any orientation

FP9 stage with C9 CGH assembly mounted

Infinitely adjustable mounting pucks,

mount the FP9 in any orientation

Metrology Platforms

Alignment of the test optic to the CGH is critical. For complex shaped optics alignment can be difficult to achieve without specific alignment references. AOM Metrology Platforms hold a test optic by its mechanical datums and provide optical targets that enable alignment to the CGH.

The benefit is a test setup that provides confidence in the alignment of the test, efficient setup in less time than a null-only test, and a production-friendly configuration for metrology of multiple parts with a single test setup.

AOM Metrology Platforms are purpose-built to accept the specific test optic form factor and testing requirements.

Learn more about how metrology platforms enable complete metrology systems when paired with a CGH and alignment strategy.