PRODUCTS

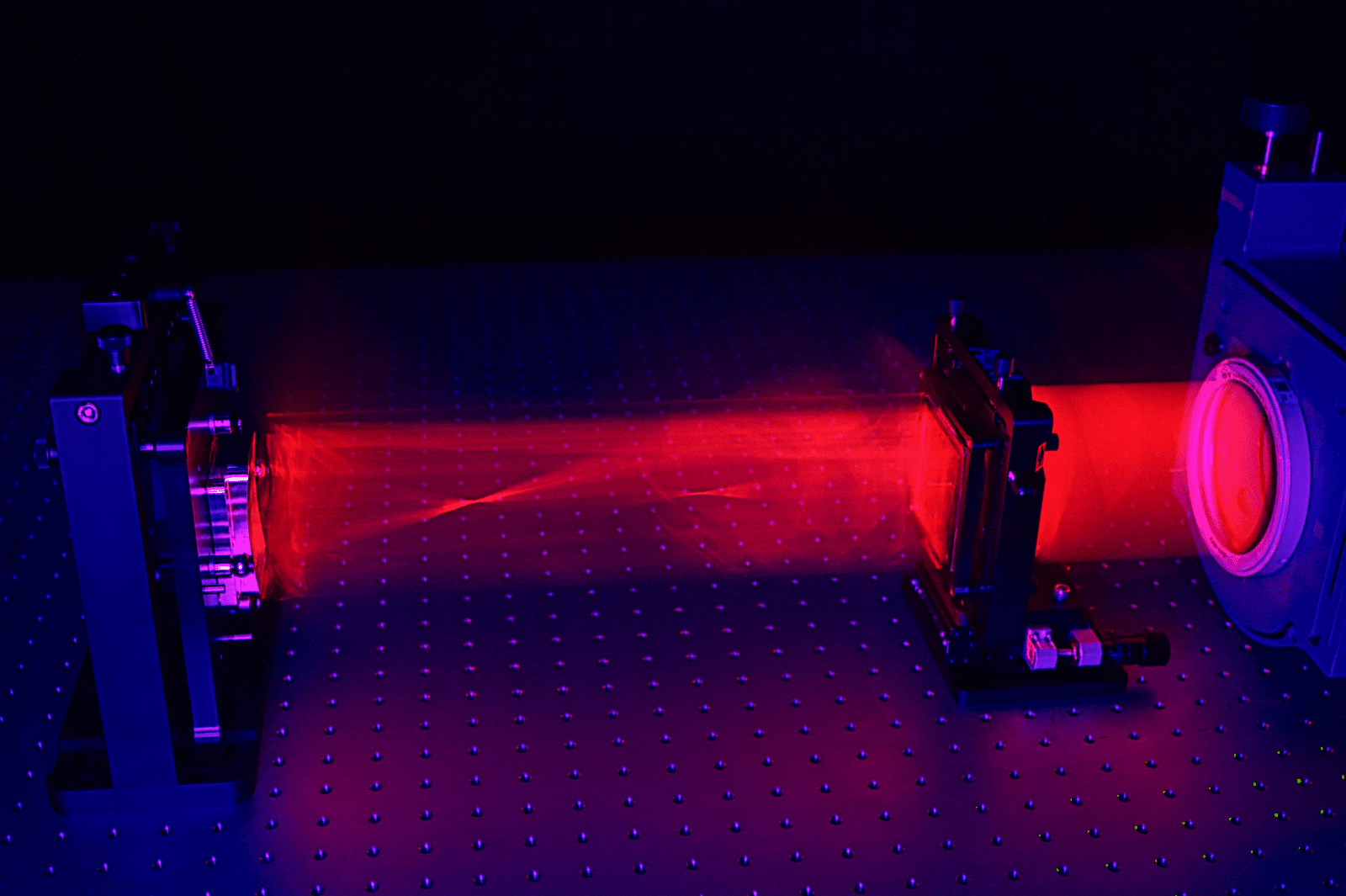

Precision Optical Metrology

AOM products and services enable precision optical metrology for the fabrication and production of complex optical components and systems.

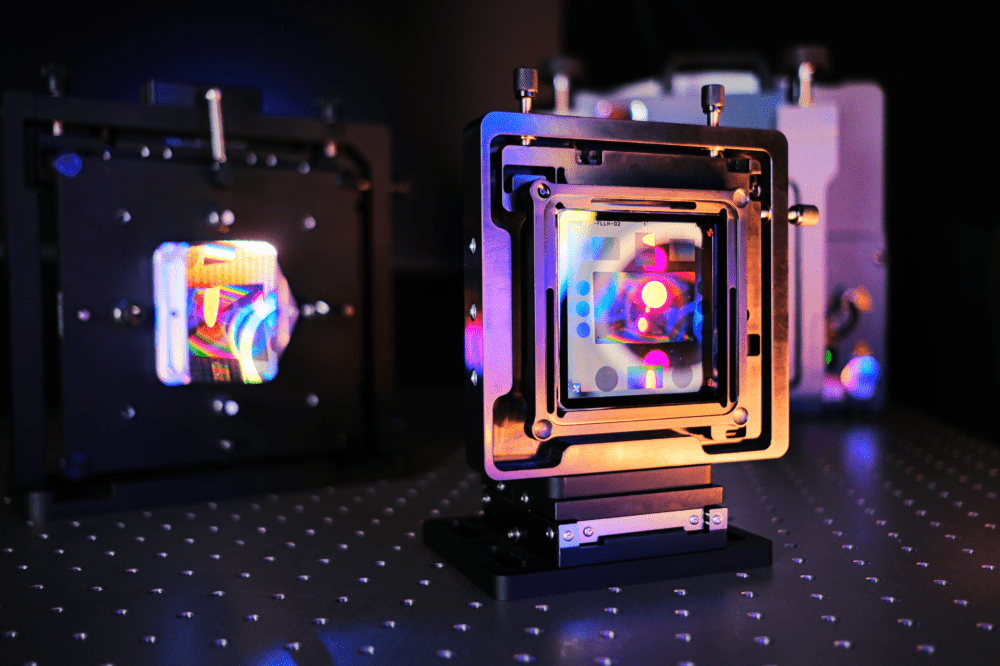

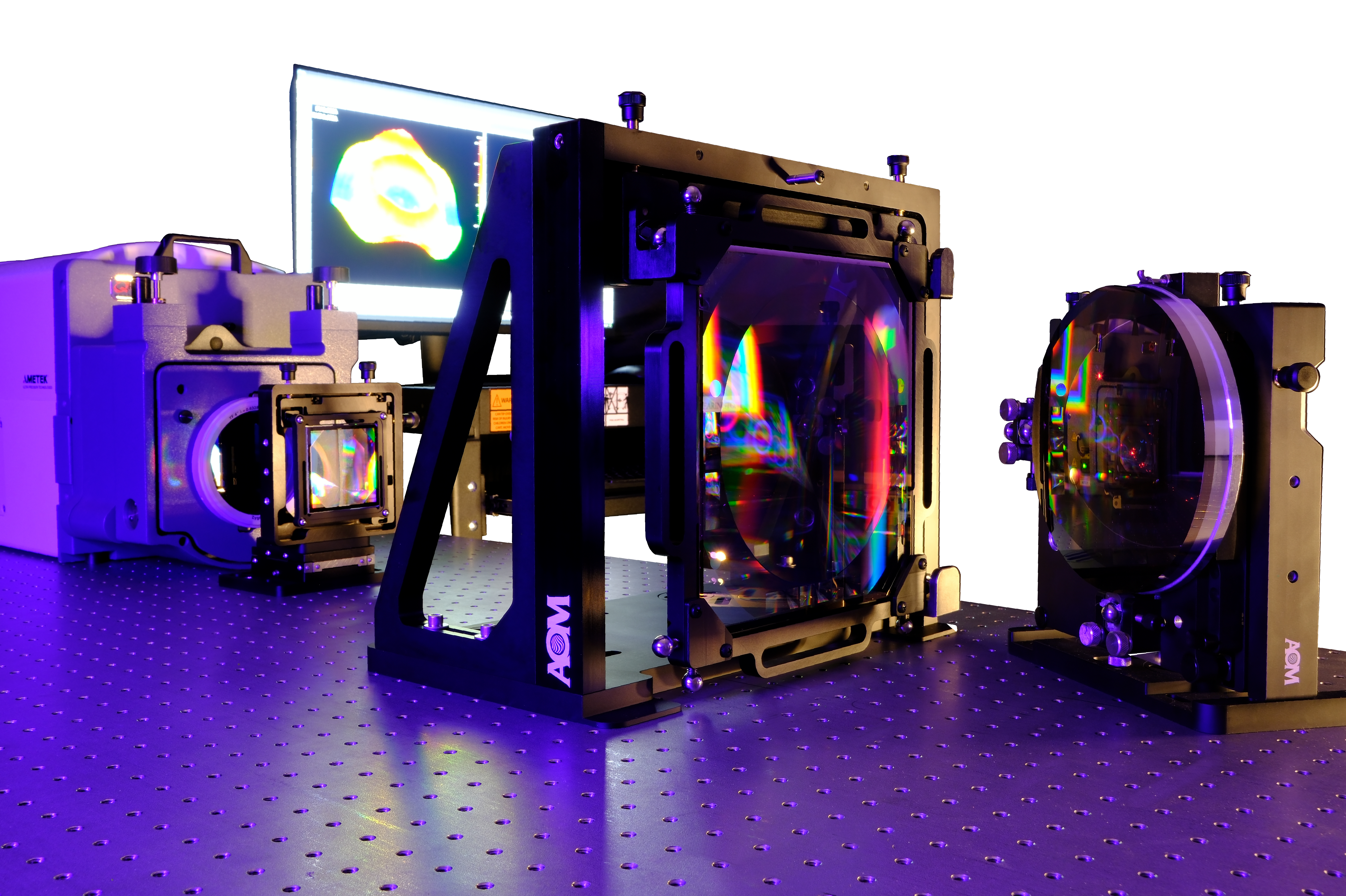

Metrology Systems

Comprehensive test setups and turnkey metrology systems for volume optics production and high-value one-off optics.

Interferometer Compatibility

AOM products are well suited to pair with a number of commercial interferometer systems including Fizeau and Twyman-Green type interferometers. Compatible models include:

- Zygo – Verifire, Dynafiz, GPI, Mark

- 4D Technologies – Accufiz, PhaseCam

- Xonox – X-fiz, X-Mini

- Apre Instruments – S-Series

- ADE Phase Shift – MiniFIZ

- WYKO

- Trioptics

- MollerWedel